Glitter is an extraordinary material, especially when it comes to shoes. It transforms ordinary footwear into something dazzling, adding a touch of magic and glamour to any outfit. The way glitter catches the light creates a sparkling effect that draws attention and makes a bold statement. Whether used in subtle accents or covering an entire pair of shoes, glitter instantly elevates the design, making it perfect for special occasions or anyone who loves to stand out. Not only does it bring an element of fun and whimsy, but it also exudes elegance, making shoes with glitter both playful and chic.

There are various types of glitter, some with larger grains and others with smaller ones. If you're unsure about which type you've chosen, feel free to contact us or drop by our store if you're nearby.

Glitter is a Non-Animal product. The glitter we use at Lola Ramona for our "Mix & Match" concept involves a series of precise steps to ensure durability, vibrant color, and even application. Here’s an overview of the production process:

Material Selection: Glitter is typically made from sheets of polyethylene terephthalate (PET) known for its durability and flexibility, or occasionally from bio-degradable alternatives for eco-friendly options.

Coloring and Coating: The PET sheets are coated with vibrant, reflective metallic or holographic colors, sometimes with multiple layers to increase shine and depth. UV-resistant coatings are added to ensure the glitter remains vibrant over time.

Cutting Process: The coated PET sheets are fed through specialised machines that cut them into consistently sized, small-grain pieces. These machines are designed to produce evenly sized grains while maintaining crisp edges for maximum sparkle.

Application on Fabric or PU Surface: For shoes, the glitter is often applied onto a base canvas fabric layer. Adhesive is evenly applied to the base surface, and the glitter is spread across it, ensuring full coverage. Large pieces require careful layering to avoid overlap and ensure a smooth texture.

Pressing and Curing: Once the glitter is spread, the material is pressed and heated to bond the glitter grains firmly onto the surface. This curing step ensures durability, allowing the glitter to withstand wear without excessive shedding.

Final Sealing: To increase longevity and prevent the glitter from flaking, a final clear coating or sealant is often applied, preserving the material’s shine and smoothness.

We've gathered some of our previous sneakers featuring glitter in the images below for inspiration. Please note that the colors in our Mix & Match collection change periodically, so the available colors may vary.

4,7 STAR REVIEWS ONLINE

4,7 STAR REVIEWS ONLINE

Rest of Europe

Rest of Europe

Denmark

Denmark Norway

Norway Iceland

Iceland Faraoe island

Faraoe island Switzerland

Switzerland Hungary

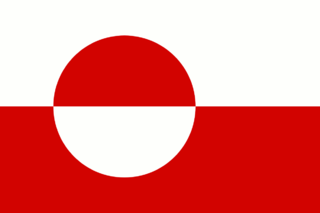

Hungary Greenland

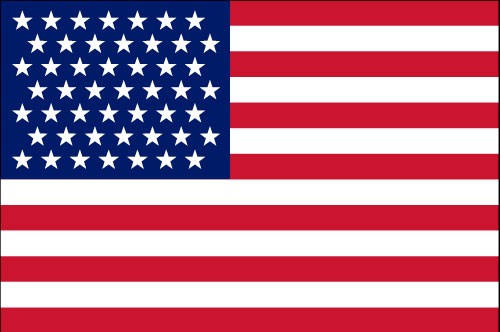

Greenland USA

USA Canada

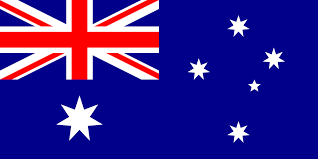

Canada Australia

Australia New zealand

New zealand UK

UK